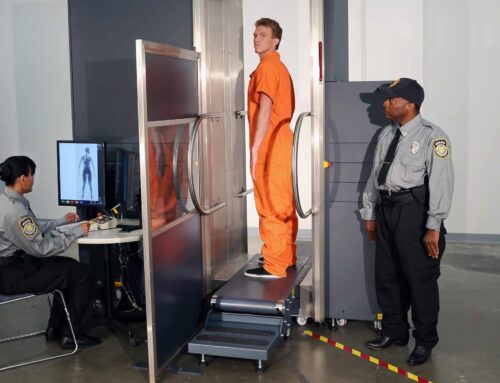

In today’s high-security environments – airports, government buildings, courthouses, and correctional facilities – security screening equipment must operate with precision. One of the most critical yet often overlooked aspects of maintaining this precision is regular calibration.

What Is Security Equipment Calibration?

Calibration is the process of adjusting and verifying the accuracy of a device’s detection capabilities. For metal detectors, x-ray scanners, and other screening equipment, this ensures the system correctly identifies threats without triggering unnecessary false alarms. Without regular calibration, even high-end machines can become unreliable over time.

Why Is Calibration Important?

Accuracy in Threat Detection

Calibrated equipment identifies weapons, explosives, and contraband effectively. A miscalibrated unit might fail to detect these items or, conversely, flag harmless objects, creating delays and security concerns.

Compliance with Safety Regulations

Agencies such as the TSA and other federal organizations have strict guidelines for screening equipment. Routine calibration ensures your facility stays compliant with these standards, avoiding fines or operational shutdowns.

Minimized Downtime and Maintenance Costs

Proper calibration reduces the risk of breakdowns. When machines work as intended, your team can avoid costly repairs and last-minute maintenance calls that disrupt operations.

Enhanced Public Trust and Operational Flow

Passengers and visitors expect fast, secure screenings. When security equipment is accurate and efficient, it minimizes wait times and builds confidence in your facility’s safety procedures.

Signs Your Equipment Needs Calibration

- Frequent false alarms or missed threats

- Irregular detection ranges

- Operator complaints or inconsistencies

- Unusual error codes or system messages

If your screening equipment shows any of these symptoms, it may be time for a professional inspection and recalibration.

How Often Should Calibration Be Done?

The frequency depends on the type of equipment, its usage level, and manufacturer recommendations. Generally, calibration should be part of your preventative maintenance schedule, ideally performed by trained technicians at least once or twice a year – or more for high-traffic locations.

Point Security provides on-site professional services that include preventative maintenance, equipment repair, radiation safety inspections, operator training, and verification of calibration inspections for the following manufacturers of security screening equipment. As your one-stop commercial security screening equipment shop, we keep many parts on hand to ensure prompt, efficient service for all our customers.